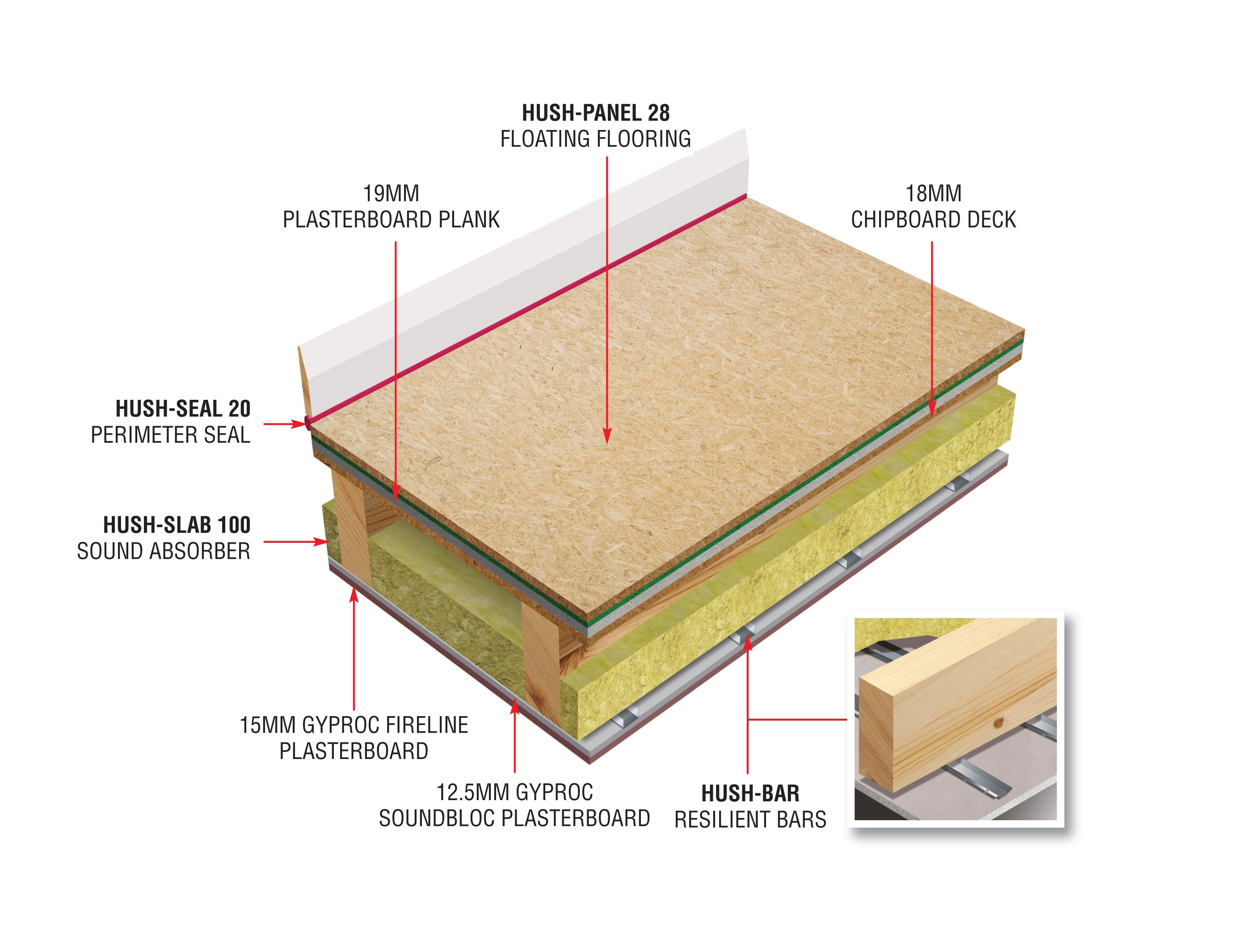

Acoustic floating floors are proven to reduce both airborne and impact sound transmission between separating floors because they decouple the floor panels from the structure through a resilient layer.

Significant sound reduction performance can be achieved through a combination of separation and cushioning providing the flooring panels are sealed properly around the perimeter. This is done using a flanking strip, such as the Hush HD Flanking Strip, with any gaps treated using an acoustic sealant like Hush Acoustic & Intumescent Sealant.

To help decide which is the correct floating floor panel to use for a project, there are four factors to consider.

Floor height build up

An obvious difference between many of the acoustic floating floor panels is their thickness. This ensures that Hush products can accommodate a wide range of project requirements and structural floor constructions.

The majority of floors are suited to the most widely used of all the Hush floating flooring panels, Hush Panel 28. This is formed by combining a P5 moisture resistant chipboard and a 10mm layer of the Hush Felt resilient layer, resulting in an incredibly versatile panel for use in the majority of material change of use projects, as well as some new build developments.

However, whilst Hush Panel 28 is actually the UK’s most specified acoustic floor panel of its kind, it may not be suitable where the floor build-up limit is restricted. In these circumstances a thinner acoustic floor panel such as Hush Panel 14 and Hush Panel 17 may be required.

In certain situations, even these thinner panels are too thick, which means one of the Hush acoustic membranes could be an effective approach, subject to the performance goals.

Density

Another consideration is the density of the floating floor product. With particularly lightweight floor structures, such as those constructed with a steel frame or some types of timber frames, the Hush Cem Panel range will need to be used. One widely used panel from this range is Hush Panel Cem 28, which has 10 kg/m2 more mass than its non-cem sister product Hush Panel 28.

In some circumstances it is really important to maximise the mass in the floor to meet the target acoustic performance, hence why Hush manufactures these heavier boards. The reason why these products add mass is due to their composition. Hush Panel Cem boards are formed of a high density cement particle chipboard, a 10mm Hush Felt resilient layer and a 5mm Hush Barrier Mat. It is a material composition that provides the extra density that is so important in blocking soundwaves.

Where a project demands particularly high acoustic performance, it will be necessary for the floor panel to provide even more mass and resilient material. In these floor designs, Hush Panel Cem 37 could be used as it features a 15mm layer of Hush Felt, compared to 10mm on Hush Panel Cem 28, plus a thicker 22mm cement particle board.

How are the floor finishes to be installed?

A further factor in deciding which floating floor panel to use is how the proposed floor finish will be installed. It is important to understand which panels best suit the proposed floor finish materials so aesthetic goals are maintained long term with no unwanted movement or deterioration in quality over time.

The Hush Acoustics floating flooring range accommodates every type of floor finish, from laminate and LVT to ceramic tiles and carpets, with specialist advice available to ensure every client achieves the best solution for their project. Certain adhesives, for example, work best with plywood topped products – a factor that could make Hush Ply 28 a better option than Hush Panel 28 or the Hush cem panels.

Target acoustic performance

Finally, the type of floating floor panel chosen will depend on the target level of acoustic performance in the separating floor. As a general rule of thumb, the more density, mass and separation that can be built into the floor construction, the more effective it will be at stopping sound transmission between the upper and lower rooms.

Given the numerous factors which can influence the maximum possible airborne and impact sound reduction level, it is best practice to seek specialist advice to achieve the right results. It is also why the Hush floating floor panel range provides a product to meet any performance goals, from compliance to ‘better’ and best.

To find out more about the range of acoustic floating flooring range, visit www.hushacoustics.co.uk/product_categories/floating-flooring or call 0114 551 8682.

A guide to choosing acoustic floating floor panels

| T | 0151 933 2026 |

|---|---|

| E | info@hushacoustics.co.uk |

| W | Visit Hush Acoustics' website |

| Unit 2, Tinsley Industrial Estate, Shepcote Way, Sheffield, S9 1TH |